The role of rebound resilience in sole grip

Rebound resilience (‘bounciness’) is one of the most tangible properties of rubbery polymers. Here, MIKE GEORGE reviews how this property can influence slip resistance, especially in the wet.

Two of the most important properties that make rubbery polymers ‘rubbery’, apart from flexibility, can be described as ‘high dry grip’ and ‘elasticity’. Indeed, polymers with such characteristics are often termed ‘elastomers’.

Rebound resilience and hysteresis

‘Elastic deformation’ implies recovery when the deforming force is removed. The extent to which this recovery takes place (in terms of energy returned) may be called ‘rebound resilience’. This is expressed as a percentage – so, for example, a steel ball dropped from 100 cm onto a rubber test slab (or, equally, a rubber ball onto a hard floor) which bounces back up to 60 cm would indicate 60 per cent rebound resilience of the rubber. The apparently missing 40 per cent of the original impact energy has mainly remained in the rubber in the form of heat generation, and some may have gone into generating sound waves from the impact. With a very large number of repeated deformations the rubber would become appreciably warm.

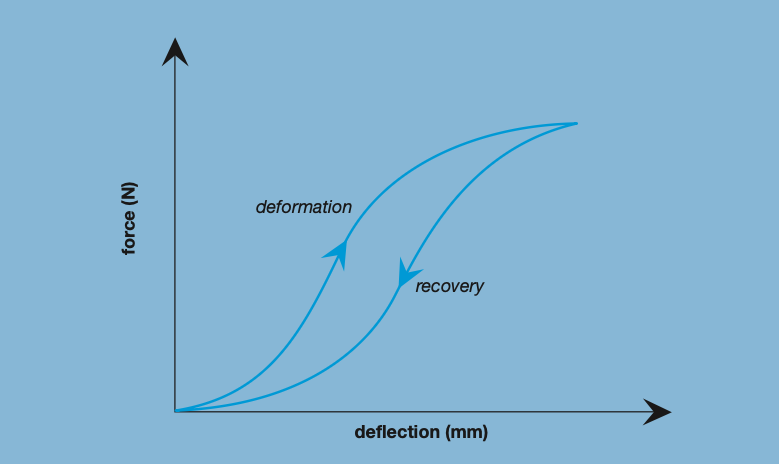

A resilient rubber is bouncy, and an unresilient rubber is ‘dead’ with minimal bounce. Most of our common experience with rubber is with the bouncy kind. Another term for permanent energy absorption into rubber is ‘hysteresis’ (see figure 1). In a rubber of low resilience, hysteresis is high and heat is developed during deformation/recovery cycles. Therefore, resilience and hysteresis are opposite sides of the same coin, rather like hardness and softness.

Figure 1: A typical ‘hysteresis’ curve. The work put in is more than the work recovered – the difference being the hysteresis (the area between the two curves)

Grip derives from friction

Within rubbery properties, we might think that grip and resilience are unconnected. However, this is not true, as will be explained. For shoe soles, ‘grip’ (or ‘slip resistance’ as we usually term it) is largely defined by the coefficient of friction between the rubbery sole and the floor surface. Friction can be considered as either the horizontal force needed to cause movement or the coefficient of friction (CoF), which is the ratio of this horizontal force to the vertical load applied (the wearer’s weight). Either way, the higher the CoF, the better for resisting and attenuating slip.

Hysteresis and resilience exhibited by rubber balls

In the racket sport of squash, the bounce of the rubber ball needs to be quite severely restricted so that the players can position themselves for the return shot without the ball bouncing wildly out of reach. Squash balls are therefore made from butyl rubber of low resilience/high hysteresis and rebound by only about 15 per cent (resilience) at room temperature. In play, the repeated violent deformations of the ball caused by racket strike and wall impact cause the rubber to heat by hysteresis to about 45°C.

At this point, the bounce has roughly doubled to 30 per cent which provides the required degree of rebound for proper play. At room temperature, the air in the ball is unpressurised and this also contributes to the lifeless nature of the ball. However, at the warmed-up temperature, the air tries to expand and becomes pressurised, largely accounting for the additional bounce. At the opposite end of the resilience spectrum, golf balls have a core of butadiene rubber and ‘bounce’ off the face of the swinging golf club with minimal hysteresis, to travel a very long way indeed.

Friction has several components

This frictional resistance to movement can be thought of as comprising several principal components. One is ‘adhesion’, whereby the atoms and molecules of each surface come into sufficiently close proximity to attract one another. A great multitude of tiny individual attractive forces can add together to something very significant. Of course, rubber, being compliant, can conform very well to the contours and roughness of another surface against which it is pressed, thus benefiting greatly from these adhesion forces. This is largely why dry rubber has good grip. Softer rubbers conform the best and therefore they produce higher levels of dry friction.

A second component contributing to overall friction is ‘deformation’ of the rubber in contact with a rough surface – not just on a macro scale but also involving ‘micro-roughness’. This is where hysteresis/resilience comes into play. On a rough floor, the rubber will deform or drape its surface around the floor surface protrusions. In the direction of motion (or attempted motion), the rubber will form leading edges pushing against these tiny obstructions and the obstructions will equally push back on the rubber, so resisting it.

However, the rubber which is immediately beyond each obstruction will also, by its elasticity, be pushing back on the leeward side of the obstruction, tending to negate the resistive force on the leading side. Hence, the net resistive force might be zero, except that hysteresis losses in the rubber mean that this return force is reduced to produce a net resistive force, as shown in figures 2a and 2b.

The failure of the rubber to fully push back on the leeward side of each obstruction produces this net resistance and, therefore, a deformation-related contribution to friction. We might also think of it as some of the kinetic energy created by the sliding action being converted to heat energy in the deforming rubber as it passes over the protrusions. This effectively soaks up or dampens some of the energy of movement.

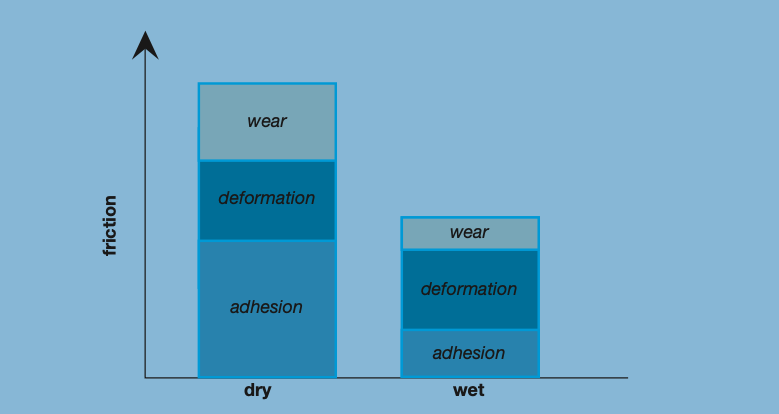

In the dry condition, this deformation component is completely dominated by the adhesion component. However, in the wet, adhesion is largely lost by water intervening between the two surfaces (the intermolecular forces only work over a tiny distance). Then deformation friction, which is still present, becomes a significant part of total friction. There is a third component to energy absorption and friction – the ‘wearing action’ of tearing off tiny particles of rubber (see figure 3).

Figure 3: Components of total friction

Friction comprises several components . |

|||

|

|

|||

| friction (total) = friction (adhesion) + friction (deformation) + friction (abrasion) | |||

|

|

|||

| Comments | Friction (adhesion)

|

Friction (deformation) . |

Friction (abrasion)

|

| High in the dry (aided by softness)Low in the wet |

Relatively uniform dry and wet and aided by low resilience (high hysteresis) . |

Higher dry than wet | |

Dry grip and wet grip

Dry grip is mainly dependent on adhesion friction, benefited by softness, and lubricated grip is mainly dependent on deformation friction, benefited by high hysteresis (low resilience). Of course, we all know that pedestrian slipping rarely occurs in the dry (unless the sole is a hard plastic). Most slipping issues – other than on ice – occur on wet or otherwise lubricated floors. Deformation friction (and, by association, rebound resilience) therefore create some interest. However, even deformation friction may be lost if the floor is so smooth that an unbroken film of liquid can exist between its surface and the sole. At this point, an aquaplaning situation exists that only an effective tread pattern can help to deal with by biting through the film and sweeping liquid to the side.

The situation with normal car tyres is slightly different. While high hysteresis would undoubtedly benefit wet skid resistance, this has to be weighed against increased rolling resistance (lower fuel economy) and rapid heat build-up which risks damaging the integrity of the tyre.

How rebound resilience is measured

Most methods involve impacting a mass onto a rubber test plate and comparing the rebound height with the drop height, expressed as a percentage. The method most used at SATRA is ISO 4662:2009 – ‘Rubber: vulcanized or thermoplastic – Determination of rebound resilience’. This contains a pendulum method (embracing both Lupke and modified Schob devices) and is suited to rubbers in the broad hardness range 30 to 85 IRHD, which covers most solings.

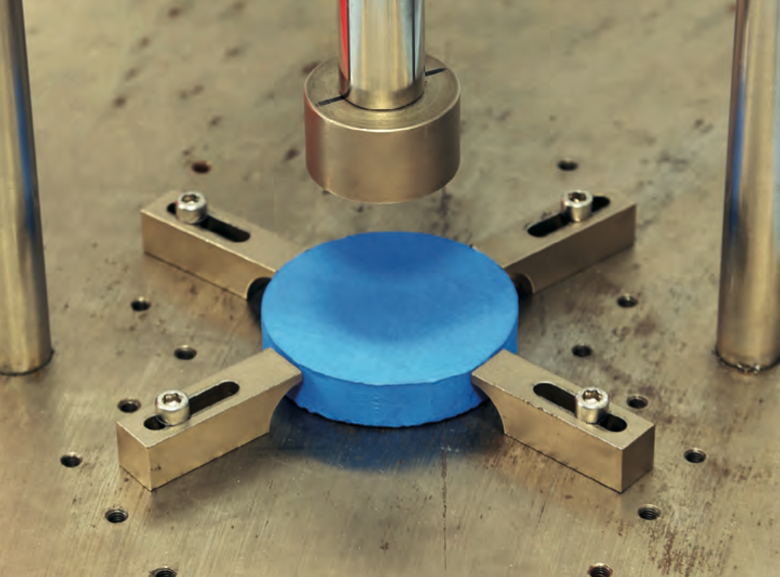

A mass (0.25 kg) with a spherical end impacts a 12.5 mm thick flat test piece, held firmly but free to bulge. The energy of the impacting mass is compared before and after impact, these energies being proportional to the release and rebound heights. The specimen is held against the upright end-face of a heavy anvil and the pendulum swings down from the horizontal to strike the test specimen at the bottom of the trajectory, when vertical. The equipment senses the pendulum angle, calculates the height of the impacting head at the top of the rebound and produces a digital read-out of the percentage rebound or resilience. SATRA manufactures this machine under reference STD 645 (see figure 4).

Figure 4: SATRA STD 645 digital resilience tester

Another apparatus capable of measuring rebound resilience is the SATRA STM 479 shock absorption tester, which is used for SATRA TM142:1992 – ‘Falling mass shock absorption test’ (figure 5). In this method, a vertically free-falling plunger of 8.5 kg mass is made to impact the test specimen which is laid on a large anvil. The rebound height is measured and compared to the drop height as a percentage, and in the usual context of this test we term it as ‘energy return’. The plunger is guided by bearings, so there is probably a little more energy lost to friction than in the ISO 4662 method. However, SATRA has demonstrated good correlation between both methods. The SATRA TM142 method is very useful for those test materials which are too soft to clamp satisfactorily on the ISO 4662 apparatus (where high compression of soft materials can allow the hammer to strike the clamping ring). High thickness can also be accommodated in the SATRA TM142 test method.

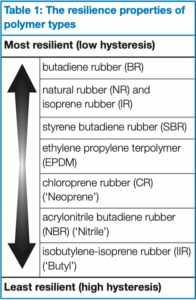

Rubber polymers ranked for resilience

Rubber polymers ranked for resilience

Various rubber polymer types have different inherent rebound resilience properties, although these may vary to some degree according to the types and quantities of the other compounding ingredients. The hierarchy for shoe sole rubbers is shown in table 1.

In practice, a balance of properties at the right price is always needed, and there are good reasons why all these rubber polymers get used in shoe soles. The mainstream materials are NR and SBR. CR – and particularly NBR – are used for industrial footwear where they offer certain desirable properties such as resistance to degradation by oils. NBR scores quite low for rebound resilience, which helps it in terms of wet grip, which is another key requirement for much industrial footwear.

Butyl is the least resilient rubber on this list, and is consequently used in specialist situations (for instance, rock climbing) where wet grip is a critical requirement. However, this comes at some cost to all-round physical performance (such as durability) compared to other polymers, and it is no surprise to see some conflict between high friction and high abrasion resistance. Therefore, for these and other technical reasons, butyl tends to be reserved for special cases where the need for wet grip is paramount.

Measuring friction

Of course, sole materials are not exclusively vulcanised rubber, and all the other available polymer types (such as PU, PVC, TR and EVA) have their own frictional properties. Nevertheless, rebound resilience will undoubtedly be one of the factors determining friction, along with hardness and tread pattern. In all cases, the amount of dry and wet friction actually available on a range of underfoot surfaces may be measured by methods such as SATRA TM144:2021 – ‘Friction (resistance to slip) of footwear and floorings, EN ISO 13287 and ASTM F2913. Hardness and resilience data can influence materials selection and help to support our understanding of the results.

Figure 5: The SATRA TM142 test method can be used to measure rebound resilience on the SATRA STM 479 shock absorption tester

Mike George has worked for SATRA for over 40 years and has been a member of the UKSRG for over 20 years. SATRA is an independent research and testing organisation established in the UK in 1919. It has technical facilities in Europe and China serving customers throughout the world. SATRA is an Approved Body in the UK and a Notified Body in the EU for various UK / European directives and regulations including personal protective equipment (PPE), which is one of SATRA’s largest sector operations. The company is considered a leading technical authority for footwear and leather.

(Published 06/2025 – First published in the SatraBulletin 01/2025)

Become a member and get involved in the UK Slip Resistance Group

More