Changes to the EN ISO 20345 standard

Hannah Coe explores the amendments to this standard which may affect safety footwear design and production.

Having last been updated in 2011 and, after much anticipation, EN ISO 20345:2022 – ‘Personal protective equipment – Safety footwear’ has now been published. The suite of test methods it draws upon has also been updated to EN ISO 20344:2021 – ‘Personal protective equipment – Test methods for footwear’. It contains a series of changes, ranging from what could be classed as ‘minor’ amendments to ‘major’ alterations. Minor changes may be defined as those that would affect specific materials and/or specific markings, whereas major changes would be amendments which would impact most footwear that has already been tested and certified.

In this article, we review the various changes within EN ISO 20345:2022 and also detail what this could mean for an already-certified product being placed on the European market.

Major changes

There have been two changes which we would term as major. The first involves the requirements and testing of slip resistance, and the second affects perforation-resistant inserts for non- metallic materials.

There were many misconceptions within the market place surrounding slip resistance with the ‘SRA’ (Eurotile and sodium lauryl sulphate), ‘SRB’ (stainless steel and glycerine) and ‘SRC’ (SRA and SRB) classifications. SRC was perceived to be the best classification of slip resistance to claim, however in reality this was not the case. To achieve an SRC rating, the design principles to achieve a good SRA and SRB result must becompromised, due to the differences in both the surfaces and lubricants. Within EN ISO 20345:2022, therefore, this has been addressed to create a system in which slip resistance can be more accurately defined within the industry.

Firstly, the conditions in which we perform the slip-resistance test on the footwear have changed. Within the previous version, the conditions related to forward heel slip and forward flat test modes. However, within the 2022 version of the standard, the forward flat slip mode has been changed to state ‘backward forepart slip’ (of the flexing area only with the heel raised clear).

In addition to this, instead of three options for showing slip results (SRA, SRB, SRC), in essence there is now only one – which would give the marking code as ‘SR’. However, this is only included if both clauses 5.3.5.2 and 6.2.10 are carried out. Clause 5.3.5.2 of EN ISO 20345:2022 refers to slip resistance tested on the Eurotile 2 with sodium lauryl sulphate (soap) solution. This is now a mandatory test within the new basic performance requirements. The requirement for forward heel slip is now expressed as ≥ 0.31 coefficient of friction (CoF). This is effectively unchanged from the previous 0.28 figure because a correction factor of 0.03 was applied, which is no longer the case. The new requirement for backward forepart slip is ≥ 0.36 (CoF) and, again, this relates to the raw data without adjustment. There is no marking code used for this clause of slip resistance, as it forms a part of the basic requirement.

If an additional (optional) claim for slip resistance is to be made, the code for this would be ‘SR’. In order to achieve this, testing must also be made in line with clause 6.2.10 and the requirements reached. This clause is new to this version of the standard. It also uses the Eurotile 2 but with a lubricant of glycerine, with the requirements of ≥ 0.19 (CoF) for the forward heel condition and ≥ 0.22 (CoF) for the backward forepart condition. Hence, the Eurotile 2 replaces the previous stainless steel test surface (used to claim the old SRB and SRC ratings), the glycerine coating is maintained, and the forward flat test mode is again replaced by the previously-mentioned backward forepart test mode.

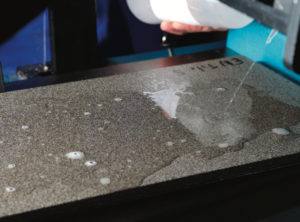

For the slip resistance test, the Eurotile 2 replaces the previous stainless steel surface used when claiming the old SRB and SRC ratings

All this slip testing still references (through EN ISO 20344:2021) the EN ISO 13287:2019 method, but is now drawing upon different options from the menu available within that method. For mounting the footwear, either a standard last or the manufacturer’s last may be used. The articulated foot used in the previously flat contact mode is therefore now redundant.

There is a third option, which is to not include slip resistance at all. The standard states: “For footwear designed for special purposes, containing spikes, metal studs or similar, and for use for very special work places (soft ground – for example, sand, sludge, forestry timber), this test is not applicable”. This would be shown as the marking symbol ‘Ø’, although this could only be claimed if the end use of the footwear fell into this category. It could not be applied to ‘conventionally soled footwear’, which would have to achieve the basic requirement.

The second change that we would class as major would cover the perforation resistance for non-metallic inserts. With the first change affecting all safety footwear on the market, this second change would only impact the footwear claiming perforation resistance with non-metallic inserts as part of their construction.

Within the previous version of the specification, there was only the one nail which gave the marking code of ‘P’.

Within the revised EN ISO 20345:2022 standard, there are two relating to non- metallic inserts: ‘PL’ and ‘PS’.

|

|

|

| Table 1: Comparison of toe cap testing pre-treatments (as components) | |

|

|

|

| EN ISO 12568:2010 | EN ISO 22568-2:2019 |

|

|

|

| 5.5.2 Effect of high temperature | 5.5.2 Effect of high temperature |

|

|

|

| 5.5.3 Effect of low temperature | 5.5.3 Effect of low temperature |

|

|

|

| 5.4.4 Effect of alkali | 5.5.4 Effect of fuel oil |

|

|

|

| 5.4.5 Effect of acid | |

|

|

|

| 5.4.6 Effect of fuel oil | |

|

|

|

.

The PL nail is the same version – 4.5 mm in diameter – that would give the older P code according to EN ISO 20345:2011. During the testing, the requirement remains the same that it must not perforate the insert before reaching 1,100 N of force during any of the four measurements. In addition, there must be no separation or delamination of the layers (such as the ‘tent effect’) during any of the tests.

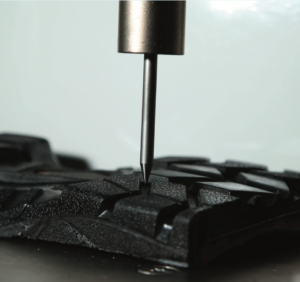

There are now two nails used to evaluate the perforation resistance of non-metallic inserts – the 4.5 mm diameter ‘PL’ and the ‘PS’, which has a diameter of 3.0 mm.

The PS nail (which has a diameter of 3.0 mm) is a new version that has been included in the specification. During the testing, the 3 mm diameter nail is pushed through the specimen and the average force of the four measurements for penetration resistance cannot be less than 1,100 N, with no single value being less than 950 N. In both cases, this testing is conducted on the sole unit containing all of the components, but with the upper removed. There are separate standards for the inserts as components themselves:

i) EN ISO 22568-3:2019 – ‘Metallic perforation-resistant inserts’, and

ii) EN ISO 22568-4:2021 – ‘Non-metallic perforation-resistant inserts’.

These standards contain a set of test protocols and requirements which the components must meet before they can be marked with the reference number of the standard.

|

|

|

| Table 2: Comparison of flexing resistance assessment criteria | |

|

|

|

| EN ISO 20345:2011 | EN ISO 20345:2022 |

|

|

|

| Spontaneous cracks are acceptable in the following circumstances:

|

Spontaneous cracks are acceptable, unless one of the following conditions occurs:

|

|

|

|

.

Minor changes

As well as the major changes detailed within the new version of the specification, there are also a number of minor changes which will now be briefly described.

Clause 5.3.2.3 – ‘Width of flange of toe caps’ is a new clause within EN ISO 20345:2022, relating to both metallic and non-metallic toecaps. There are two requirements for the flange width, one for metallic toecaps ≤ 12 mm and one for non-metallic toecaps ≤ 15 mm.

Clauses 5.3.2.6 and 5.3.2.7 – ‘Impact and compression resistance’ is another minor change, which relates to toe caps with these requirements. While the minimum clearances remain the same, the assessment criteria after the testing have slightly changed. The requirement remains that the toe cap cannot crack to allow light to be seen, but now also states that there must be no delamination occurring. Additionally, the UK shoe sizing has been removed from the requirements. This now only indicates European sizing.

Clause 5.3.2.5 – ‘Behaviour of non- metallic toe caps (thermal and chemical).’ As mentioned earlier, EN ISO 20345:2022 refers to separate testing standards for toe caps. These are EN ISO 22568-1:2019 for metallic toe caps and EN ISO 22568-2:2019 for non-metallic caps. Before these were split into individual parts for the different materials and components, EN ISO 12568:2010 was a ‘cover-all’ standard containing the requirements for metallic and non-metallic toecaps and perforation-resistant inserts.

Specifically in reference to the environmental treatments for non-metallic toecaps, there have been two changes. The first amendment is that the effects of both alkali and acid have been removed for the toe cap pre-treatments, leaving only the high temperature, low temperature and fuel oil pre-treatments (see table 1).

The second change is the conditioning time for the effects of high temperature. The previous version of the sub-standard referred to an initial exposure of 60°C for four hours with a further exposure of 45°C for another 18 to 20 hours. The new version refers to an initial exposure of 70°C for 168 hours, with a further exposure to 45°C for 17 to 19 hours, significantly increasing the exposure and testing times.

Clause 5.3.3 – ‘Leakproofness’ contains a minimal change to exclude from the requirement ‘Design A’ of Class II footwear with an open heel area or perforations.

Clause 5.3.6 – ‘Innocuousness’. EN ISO 20345:2022 now explicitly states within the requirements that leather parts must be tested for both pH and the presence of chromium VI. This clause retains the paragraph concerning safety footwear not adversely affecting the health and hygiene of the user, which incurs additional chemical testing to ensure that this requirement is met.

Clause 5.3.7 – ‘Seam strength (hybrid footwear)’ is a new clause within EN ISO 20345:2022. This solely relates to hybrid footwear where the materials in areas ‘A’ and ‘B’ are connected. It contains a requirement for a seam strength of at least 10 N/mm.

Clause 5.4.4 – ‘Upper tensile properties’. For the most part, the requirements within this clause remain the same – apart from the modulus at 100 per cent elongation (N/mm2), this has changed from 1.3 to 4.6 in EN ISO 20345:2011 to ≥ 1.0 within EN ISO 20345:2022.

Clause 5.4.5 – ‘Upper flexing resistance’ contains a slight amendment similar to the impact and compression clauses. In addition to the requirement of no cracking before the required number of flexes, there is also a requirement that there is to be no damage – such as pinholes and cracks – that are visible to the naked eye.

Clause 5.4.6 – ‘Upper water vapour permeability and coefficient’. Within the new version of the standard, this clause contains different criteria, depending on the upper materials used. Since the last version of the standard, more non-water vapour permeable materials have become available, so these are now being addressed within the new version.

The first criterion remains mainly the same as that in EN ISO 20345:2011, except for an additional requirement stating: “A maximum area of 10 per cent of non-water vapour permeable materials is acceptable when measured according to ISO 20344”.

The second criterion is for any footwear containing more than 10 per cent (but less than 25 per cent) of non- water vapour permeable upper materials. This indicates that any footwear containing > 25 per cent of non- permeable materials would therefore fail these requirements.

|

|

||

| Table 3: Classification changes | ||

|

|

||

| Catergory | Class 1I / Classs II | Additional requirements |

|

|

||

| SB | Classs I / Class II | . |

|

|

||

| S1 | Classs I | As SB plus: • closed heel area • energy absorption of seat region • antistatic |

|

|

||

| S2 | Classs I | As S1 plus: • water penetration and absorption |

|

|

||

| S3 (metal insert type P) S3L (non-metal insert type PL) S3S (non-metal insert type PS) |

Class I | As S2 plus: • perforation resistance according to the type • cleated outsole |

|

|

||

| S4 | Class II | As SB plus: • closed heel area • energy absorption of seat region • antistatic |

|

|

||

| S5 (metal insert type P) S5L (non-metal insert type PL) S5S (non-metal insert type PS) |

Class II | As S4 plus: • perforation resistance according to the type • cleated outsole |

|

|

||

| S6 | Class I | As S2 plus: • water resistance of whole footwear |

|

|

||

| S7 (metal insert type P) S7L (non-metal insert type PL) S7S (non-metal insert type PS) |

Class I | As S3 plus: • water resistance of whole footwear |

|

|

||

Clause 5.5.4 – ‘Lining water vapour permeability and coefficient’. Similar to previous clauses, this contains a slight amendment that details which materials are relevant to this testing and which are not. It states: “No test is required when lining material is present only in the heel area (5.3.2). When there is no stiffener or the stiffener is perforated, the material shall comply also WVP”. The requirement stating that there is no requirement to test unlined stiffeners remains as a requirement rather than a note.

Clause 5.7.3 – ‘Insole and insock water absorption and desorption’. While there are no changes to the requirements within this clause, some information has been added to explain how to test an insole which is covered by a membrane lining.

Clause 5.7.4 – ‘Insole and insock abrasion resistance’. As above, for the insocks there are no changes to the testing or the requirements. However, for the insoles, there is new performance requirement and assessment criteria. The requirement now denotes that the test piece cannot be less than 66 per cent of the original thickness after testing.

Clause 5.8.2.1 – ‘Outsole thickness’. Most requirements within this clause remain unchanged. However, there is a new requirement for mounted (cemented) outsoles, which relates to the full outsole thickness ‘d4’, with cavities not being less than 2 mm.

Clause 5.8.5 – ‘Outsole flexing resistance’. The main change for this requirement is the damage to the metallic insert if it is present (table 2).

Clause 6.2.2.1 – ‘Partially Conductive’. A simple change in terminology from ‘conductive’.

Clause 6.2.5 – ‘Water resistance’. Within this clause, the requirement has changed from ≤ 3 cm2 to ‘no water penetration detected’.

Clause 6.2.6 – ‘Metatarsal protection’ is unchanged with respect to performance requirements. However, there is now an additional requirement to ensure that the metatarsal device is supported by the toe cap during the impact test and must remain in place after testing.

Clause 6.2.7 – ‘Ankle protection’. While the transmitted force requirements remain unchanged, the requirement and procedure for assessing the dimensions and position of the protectors have now been amended.

Clause 6.2.9 – ‘Scuff cap abrasion’ is a new clause and requirement within EN ISO 20345:2022, and relates to any scuff caps being placed over the front of the footwear when the ‘SC’ marking code is being used. The scuff caps must not develop any holing through the full thickness of the component before 8,000 cycles during the abrasion testing.

Clause 6.4.2 – ‘Fuel oil resistance’ has a minor change to better denote the materials that are required to be tested. EN ISO 20345:2022 now states: “All visible outsole materials”.

Clause 6.4.3 – ‘ladder grip’. Similar to clause 6.2.9, this is a new clause and optional/additional requirement in the standard. This clause contains several sub-clauses highlighting performance requirements related to the design, cleat height in the waist area, and heel breast dimensions, all of which are very similar to the requirements contained within EN 15090:2012.

Classification changes

The grouping of codes has also slightly changed within the new version of this standard in order to accommodate water resistance of footwear and different nail perforation claims. The requirement for fuel oil resistance has also been removed from group classifications (see table 3).

Certification changes

The user information and marking clauses generally remain the same as the previous version of the standard. There have been a few inclusions which bring them into line with other product standards – for instance, obsolescence requirements, plus requirements from the European PPE Regulation (EU 2016/425) such as including the name and address of the manufacturer onto the labels themselves (PPE Regulation article 8, clause 6).

Another minor difference is that the standard wording which is required to be included within the user information for both the ‘antistatic’ and ‘partially conductive’ claims has slightly changed.

The standard requires the new version of the wording to be included. Similarly, there are new statements which are to be included for perforation resistance, along with notes included referring to the new Annex B (assessment of the footwear by the wearer) and Annex C (guidance on slip resistance).

The relevant marking codes for additional requirements are shown in table 4.

|

|

|||

| Table 4: Marking codes according to EN ISO 20345:2022 | |||

|

|

|||

| Requirement | Code | Class I/Class II | Additional information |

|

|

|||

| Perforation resistance (metalinsert Type P) | P | Class I/Class II | |

|

|

|||

| Perforation resistance(non-metal insert TypePL) | PL | Class I/Class II | 4.5 mm diameter nail |

|

|

|||

| Perforation resistance(non-metal insert TypePS) | PS | Class I/Class II | 3.0 mm diameter nail |

|

|

|||

| Partially conductivefootwear | C | Class I/Class II | Can only be either partially conductive orantistatic |

|

|

|||

| Anti-static footwear | A | Class I/Class II | |

|

|

|||

| Heat insulation of outsolecomplex | HI | Class I/Class II | |

|

|

|||

| Cold insulation of outsolecomplex | CI | Class I/Class II | |

|

|

|||

| Energy absorption of seatregion | E | Class I/Class II | |

|

|

|||

| Water resistance | WR | Class I | |

|

|

|||

| Metatarsal protection | M | Class I/Class II | |

|

|

|||

| Ankle protection | AN | Class I/Class II | |

|

|

|||

| Cut resistance | CR | Class I/Class II | |

|

|

|||

| Scuff cap abrasion | SC | Class I | |

|

|

|||

| Slip resistance (ceramic floor tile andglycerine) | SR | Class I/Class II | No marking if tested just to 5.3.5.2 . SR marked if tested in line withboth 5.3.5.2 and 6.2.10 . Ø marked if no slip-resistance testcompleted (studded/spikedfootwear) |

|

|

|||

| Water penetration andabsorption | WPA | Class I | Upper test |

|

|

|||

| Resistance to hot contact | HRO | Class I/Class II | Outsole test |

|

|

|||

| Resistance to fuel oil | FO | Class I/Class II | Outsole test |

|

|

|||

| Ladder grip | LG | Class I/Class II | Outsole test |

|

|

|||

| Not tested for slipresistance | Ø | Class I/Class II | |

|

|

|||

.

Certification – what to do now

As detailed in this article, there are two major changes which we deem would affect most of the footwear currently certified against PPE Regulation 2016/425, and SATRA has a list of designated tests which is available from the footwear team (contact details below). This list highlights the testing that we would require to update current test reports of already-certified products. It would not cover specific claims, as these would be decided on a case-by-case basis dependant on the claims that are being made.

Although EN ISO 20345:2022 has been published, at the time of writing it is not the harmonised or designated version. The older EN ISO 20345:2011 still remains the harmonised version, therefore meaning that this has the presumption of conformity.

SATRA currently has no plans to withdraw any certificates that are approved using EN ISO 20345:2011. Thus, footwear can continue to be placed on the EU/UK markets to this version and there is no mandatory requirement to update at this time.

As EN ISO 20345 is part of a series, including EN ISO 20346 and EN ISO 20347, most points within this article also relate to the new versions of EN ISO 20346:2022 and EN ISO 20347:2022.

Hannah Coe works for Satra for over 10 years. Satra is an independent research and testing organisation established in the UK in 1919. It has technical facilities in Europe and China serving customers throughout the world. Satra is an Approved Body in the UK and a Notified Body in the EU for various UK / European directives and regulations including personal protection equipment (PPE), which is one of SATRA’s largest sector operations. The company is considered a leading technical authority for footwear and leather.

For over 20 years the UKSRG has a member of Satra and the exchange of knowledge is for both parties mutually beneficial.

Published 06/2023 – First published in the SatraBulletin 01/2021

..

Become a member and get involved in the UK Slip Resistance Group

More