Liability in a Slipping Case

Ben Powers of Munro Instruments Ltd recently provided expert witness services in a slipping case (H11YJ740). The judgement of that case revealed insights both into how similar cases may be handled, and how slipping claims may be avoided in the first place. The Author is not a legal expert, and the following cannot be considered legal advice.

Accident Summary

The Claimant was crossing a composite decking walkway in wet weather on a busy holiday park. She was wearing ‘sensible shoes’, and the decking was in a condition commensurate with its external location and periodic cleaning (i.e. not significantly or excessively soiled). She slipped and fell to her injury. Whilst she did not suffer broken bones, she did suffer long term pain and loss of earnings as a result of the fall.

Test Data Summary

A specification sheet was produced at court that gave a manufacturer’s rating of 37PTV (wet with #96 rubber).

Two experts attended site to conduct their own investigations, producing values of 33PTV and 36PTV respectively (lowest directional values, wet, with #96 rubber).

The holiday park did not conduct their own risk assessment test measurements or if they did, they failed to present these at court.

The Judge ruled that the actual level of slip resistance was 33PTV, whilst noting that it was unlikely to represent the slip resistance at the time of the accident, but that it was the best available evidence. 33PTV is classified as a ‘moderate risk of slip’ in line with HSE and UKSRG Guidance.

Lay Witnesses

The Claimant gave evidence that she slipped and that the decking felt slippery.

The Defendant called two lay witnesses, a maintenance manager and a cleaning supervisor, who both gave evidence that the decking didn’t feel slippery and that they weren’t aware of any slipping accidents occurring. Neither could attest to any slip testing undertaken as a part of a risk assessment programme but did claim slip risk was assessed by cleaners using a tick box system.

Expert Witnesses

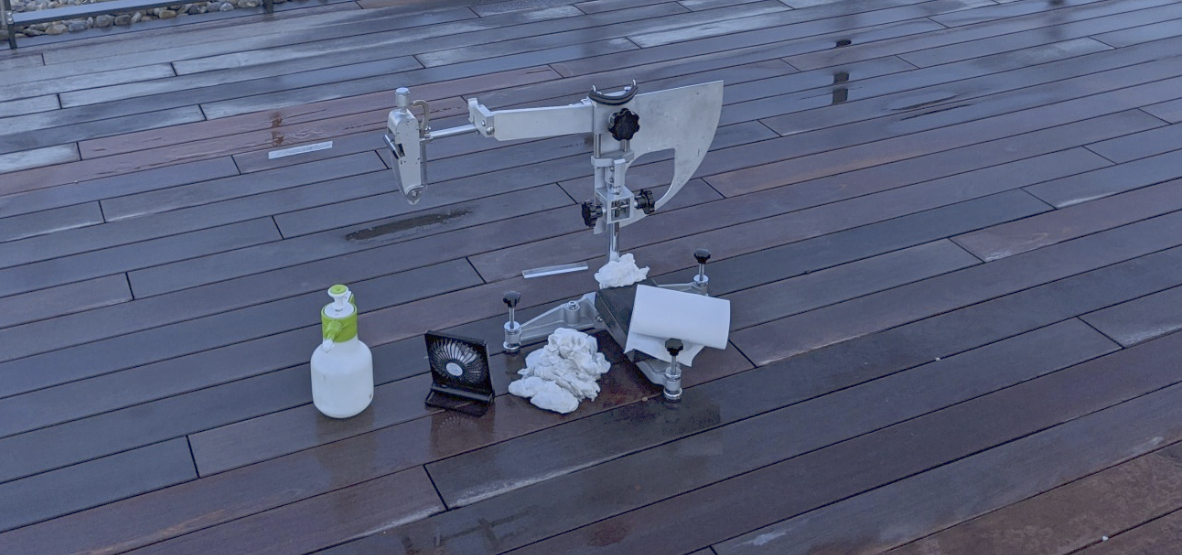

There was disagreement on how the decking should be tested and the results interpreted, with one expert failing to test directly across the profile (for fear of damaging the machine) and one expert testing only directly across the profile (as movement was generally constrained to this direction of travel).

Where testing had been conducted in a similar direction and location, results between experts varied by only 1PTV.

The Author argued that the decking failed to achieve 36+PTV in the conditions of end use consistently, and so (whilst it may not present a significant risk of slipping) it could not be described as meeting the criteria for a ‘low risk of slip’.

The opposing expert argued that the values lay so close to the ‘low risk of slip’ that this, coupled with the constrained direction of movement and lack of evidence of other slip accidents, meant the surface could not be considered to present a slipping hazard.

Judgement

The Judge was content that the Claimant slipped, and that she slipped because the surface was slippery.

The question of whether the surface was reasonably safe was identified as the crux of the argument. Here he preferred the Author’s evidence, and when assessing the Author’s 33PTV against the 36PTV ‘low risk’ benchmark, found that the surface was “not reasonably safe when wet”.

The Judge noted that the Defendant couldn’t rely on the input of external specialists, as the manufacturer’s 37PTV specification document was produced at the last minute and there was no evidence of it having been considered prior to the accident. He further noted that an expert specialist had assessed the surface post-accident and found that it failed to meet the 36+PTV ‘low risk’ threshold.

The Judge found that the Defendant had not taken reasonable care. He commented that the decking was likely to have deteriorated from the manufacturer claimed 37PTV, particularly when considering that the manufacturers specified cleaning regime had not been followed. He noted that no proper risk assessment had been conducted, and no remedial action taken to mitigate the risk of slipping.

Learning Points

It seems that responsible parties installed appropriate anti-slip decking, supported by the manufacturer’s 37PTV rating. The “fit and forget” approach is a common one, but this was not enough to save them from the verdict. It was noted during the case that no subsequent slip testing had been carried out, and that cleaning was not conducted in line with manufacturer’s guidance. This situation is common and could have been improved by; post installation slip testing to verify claimed performance, better cleaning regimes reflecting manufacturers guidance, and periodic slip risk assessment.

The Judge determined the slip resistance of this surface as 33PTV. This is only a small margin under the 36PTV ‘low risk’ classification and represents a ‘moderate’ slip risk rather than a ‘high’ slip risk. Despite this, the Judge found responsible parties had not fulfilled their duty of care in providing a safe surface. Those responsible for floor surfaces would do well to ensure they exceed the 36PTV boundary in the conditions of end use if they are to effectively defend similar claims.

When determining the real slip resistance of the surface one expert claimed 33PTV whilst the other claimed 43PTV. In Court the application of the UKSRG Guidelines was discussed in great detail. When conducting testing and interpreting the results in line with the Guidelines, the 43PTV expert’s classification of the surface effectively changed from a safe ‘low risk’ to an unsafe ‘moderate risk’. When assessing slip risk and seeking to ensure a safe surface in the eyes of the law, responsible parties should look to ensure testing is conducted strictly in accordance with UKSRG Guidelines.

In this case, and in many similar cases, effort was made to rely on accident statistics to show that the surface was ‘safe’ and that this particular slip was an isolated incident. It should be noted that even if the accident is isolated, this does not provide responsible parties with a ‘get-out-of-jail-free card’. The strength of accident statistics will depend heavily on reporting systems, how detailed they are, and how relevant they are to the particular accident type. The generic, “We have x hundred thousand visitors and only y slips” argument is not particularly compelling where the safety of a small part of the estate is under scrutiny and the accident reporting system can’t readily show appropriate records to the Judge.

A competent slip risk assessment incorporating slip testing in line with UKSRG Guidelines would likely have prevented the material accident and associated costs for responsible parties. It is likely than an assessment would have shown a loss in slip resistance performance, advised improved cleaning regimes, and informed remedial works such as retrofitted ‘grip strips’ which were present in the holiday park elsewhere. It is very likely that such an assessment could have been repeated at many locations around the holiday park, and subsequent improvements funded, for less than the cost of dealing with this single slip accident case.

—

This article was written by Ben Powers BSc (Hons) TechIOSH MAE. Ben spends a small proportion of his time providing expert witness services, whilst the majority of time is spent conducting slip risk assessments for responsible parties looking to reduce accident rates and improve defensibility of slip claims. Through Munro Instruments he is able to provide direct support to flooring manufacturers and health and safety professionals seeking slip risk assessments, or service, repair, calibration, training and consumables to those operating a Pendulum for their own slip tests.

See www.munroinstruments.com and www.sliptest.co.uk for more information.

Published 06/2023

Become a member and get involved in the UK Slip Resistance Group

More